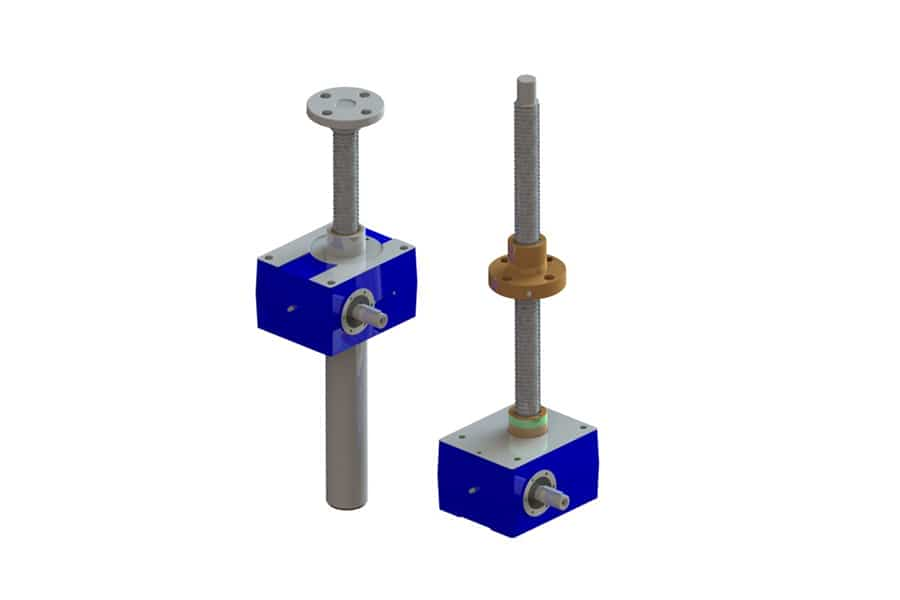

The Unsung Heroes: Worm Shafts and Rotating Mechanisms in Screw Jacks

Screw jacks are workhorses in linear motion applications, but their operation relies on a hidden hero – the worm shaft and its associated rotating mechanism. Let’s delve into the world of worm gears and explore how they translate rotation into the powerful linear motion of a screw jack:

The Worm Shaft: The Rotational Powerhouse

- Threaded Design: Unlike a traditional axle, a worm shaft has a helical thread along its surface. This thread resembles a screw, but with a much larger lead angle (the angle between the thread and the shaft axis).

- Transferring Torque: The worm shaft receives torque (turning force) from a motor or other rotating source. This torque is what allows the screw jack to lift or push significant loads.

The Worm Gear: The Perfect Partner

- Complementary Shape: The worm gear is a specialized gear designed to mesh with the worm shaft’s thread. It typically has a gear tooth pattern that is perpendicular to the gear’s face.

- High Gear Ratio: A key feature is the significant difference in size between the worm shaft and the worm gear. This creates a high gear ratio, meaning a small rotation of the worm shaft translates into a larger number of rotations of the worm gear.

The Magic of Torque Multiplication:

- Amplifying Force: The high gear ratio plays a crucial role. While the worm shaft transmits a significant amount of torque, the worm gear rotates at a much slower speed. However, due to the gear ratio, this slower rotation translates into a much higher torque output at the worm gear.

- Linear Motion from Rotation: The worm gear is often connected to the screw jack’s lead screw (threaded shaft). As the worm gear rotates, its teeth mesh with the lead screw’s threads, causing the lead screw to translate linearly along its axis. This linear motion is what allows the screw jack to lift or push objects.

Additional Points to Consider:

- Irreversibility: One key characteristic of worm gear drives is their irreversibility. While the worm shaft can easily turn the worm gear, it’s very difficult (and often impossible) to rotate the worm gear and force the worm shaft to turn. This self-locking property is a valuable feature in screw jack applications, preventing loads from moving downwards unless the worm shaft is rotated.

- Friction and Efficiency: Worm gear drives do experience more friction compared to some other gear types. This can lead to some energy loss and heat generation. However, the high torque multiplication and self-locking ability often outweigh this drawback for screw jack applications.

Conclusion:

The seemingly simple combination of a worm shaft and worm gear within the rotating mechanism forms the heart of a screw jack’s operation. By understanding the interplay between these components, we gain a deeper appreciation for the power and efficiency screw jacks bring to linear motion tasks across various industries.